For the bustling whole world of elegance and individual treatment, couple of markets capture the creative imagination quite like fragrance and cosmetic manufacturing. The intricate process of producing fragrances and cosmetics incorporates art, scientific research, and a deep understanding of consumer choices. As global need for one-of-a-kind scents and appeal products continues to climb, the role of innovative perfume manufacturing, cosmetic production, and well-appointed perfume manufacturing facilities has actually never been even more crucial. This write-up discovers the remarkable landscape of fragrance and cosmetic production, focusing on the procedures involved, the innovation used, and the fads shaping the market today.

The Essence of Perfume Manufacturing

1. Understanding Scent Composition

The heart of perfume production hinges on the fragile balance of different aromatic compounds. These can be derived from all-natural resources ( crucial oils, essences) or artificially developed in research laboratories. The main groups of scent notes include:

Leading Notes: The first fragrances that are viewed upon application, typically citrus or light flower.

Center Notes: Additionally referred to as heart notes, these arise once the top notes discolor, often identified by flower, fruity, or flavor fragrances.

Base Notes: The fragrances that remain the longest, usually comprised of heavier active ingredients like vanilla, musk, or woodsy scents.

2. The Manufacturing Refine

The perfume production process commonly entails a number of essential steps:

Principle Advancement: This phase entails creative brainstorming to identify the style and target audience for the fragrance.

Sourcing Ingredients: Suppliers resource high-quality resources, both all-natural and artificial, to develop the fragrance. This commonly includes partnerships with regional farmers and providers.

Blending: Specialists in fragrance formula carefully blend the selected components in specific ratios to develop the desired aroma account, frequently involving models and adjustments.

Aging: Comparable to great wine, several fragrances gain from aging. This permits the scent to develop and establish a richer fragrance gradually.

Bottling and Packaging: Once the desired scent is attained, it is bottled in visually pleasing containers, commonly designed to improve the overall branding and consumer experience.

The World of Cosmetic Manufacturing

1. The Range of Cosmetic Products

Aesthetic manufacturing encompasses a vast selection of items, consisting of skin care, makeup, haircare, and body care items. Each group requires specialized understanding and techniques for solution:

Skincare Products: These include moisturizers, lotions, and cleansers, frequently focusing on particular skin concerns such as hydration, anti-aging, or acne therapy.

Makeup Products: This category includes foundations, lipsticks, eye shadows, and more, each with unique formulation difficulties to accomplish wanted color, appearance, and long life.

Haircare Solutions: From shampoos to designing products, hair care formulas concentrate on cleansing, nourishing, and shielding hair while giving cosmetic charm.

2. The Manufacturing Refine

The actions involved pabrik parfum in cosmetic production are rather comparable to those in perfume manufacturing yet tailored to satisfy the certain demands of each item kind:

Research and Development: Manufacturers take part in considerable research to create ingenious products that meet market needs and regulatory standards.

Formulation: Drug stores and aesthetic researchers produce the product solutions, ensuring security, efficacy, and security via controlled research laboratory problems.

Checking: Products go through rigorous screening for quality assurance, including stability tests, skin-related tests, and allergy testing to guarantee security for consumers.

Manufacturing: Sophisticated equipment is usually used for large manufacturing, enabling regular quality and performance in the production process.

Packaging: Like perfumes, cosmetics are packaged in visually appealing, useful containers that align with branding and customer preferences.

The Role of Perfume Factories

1. Development and Technology

Perfume manufacturing facilities are manufacturing facilities equipped with advanced technology to support the complicated procedures involved in producing fragrances and cosmetics. These factories typically feature:

Advanced Extraction Techniques: Techniques such as heavy steam distillation and cool pushing to obtain crucial oils and fragrant essences from natural resources successfully.

Automated Assembly Line: Automation in manufacturing boosts performance, decreases human error, and allows for raised manufacturing capability.

Quality Assurance Labs: Fragrance manufacturing facilities commonly keep strenuous quality assurance criteria to guarantee that each batch meets exacting specifications and consumer assumptions.

2. Satisfying Consumer Demand

The international demand for one-of-a-kind and high-grade fragrances and cosmetics calls for fragrance factories to be versatile and cutting-edge. Makers should react to patterns, seasonal launches, and changing consumer preferences promptly.

Sustainability Practices: Increasingly, consumers are attracted to brands that prioritize sustainability. Numerous perfume manufacturing facilities execute environmentally friendly techniques, such as sourcing natural materials properly, minimizing waste, and making use of eco-friendly product packaging.

Modification: With the advent of tailored scents and cosmetics, some manufacturing facilities are introducing to supply bespoke manufacturing alternatives, allowing consumers to develop customized products according to their choices.

Patterns Shaping the Market

1. All-natural Components

There is a expanding pattern in the direction of natural and natural ingredients in both fragrance and cosmetic manufacturing. Customers are coming to be more familiar with the components in their items and are increasingly seeking those that are devoid of damaging chemicals. Suppliers are responding by sourcing sustainable and organic materials to fulfill this need.

2. Clean Beauty Motion

The clean appeal motion stresses openness, safety, and ethical manufacturing practices. Brand names are focusing on producing solutions that omit unsafe active ingredients while ensuring high performance. This trend is reshaping the formula and manufacturing practices of cosmetics.

3. Technological Innovations

From AI-driven fragrance development to making use of increased truth for virtual try-ons in cosmetics, technological developments are transforming the way products are developed and marketed. Makers who embrace these innovations are likely to obtain a competitive edge.

4. Customization and Customization

Customers are significantly looking for customized products tailored to their unique demands and preferences. This pattern is pushing makers to reconsider conventional product and supply adjustable options, whether in fragrance or cosmetic formulas.

Final thought

The areas of fragrance production and cosmetic manufacturing stand for a remarkable mix of art and scientific research, driven by development and consumer demand. As the market remains to develop, the function of fragrance manufacturing facilities in creating top notch, special items is vital. By accepting sustainable practices, progressing modern technology, and replying to transforming customer choices, producers can grow in this affordable landscape.

For any person curious about the world of charm and scent, recognizing the intricate procedures involved in crafting perfumes and cosmetics offers beneficial insight into exactly how these cherished products come to life. As the sector expands and adapts, it will be amazing to see exactly how creative thinking and technology remain to shape the future of fragrance and cosmetics.

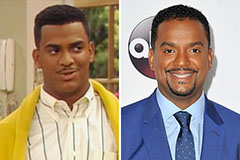

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Robbie Rist Then & Now!

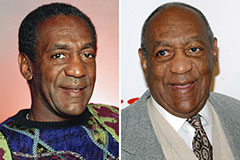

Robbie Rist Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!